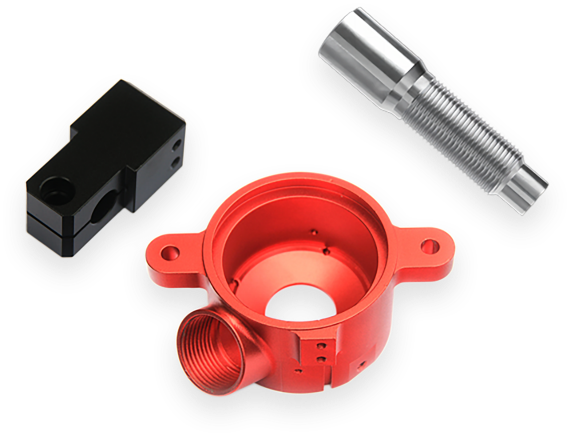

The material is one of the most important determinants of the cost and quality of your finished product, so we’re here to help you choose wisely. When analyzing your CNC machining project requirements, it’s important to consider the properties of various materials and how they affect performance, cost, and lifespan. While some CNC machining materials are more commonly used than others, almost any metal or plastic can be machined. At HENSEN, we use a variety of metals to make the parts you need. Here is a list of our most common used materials:

HENSEN has rich experience in sheet metal engineering and manufacturing, and we offer a wide range of material, surface finish, and manufacturing options for small and large-scale projects.

HENSEN has rich manufacturing experience in injection molding and can offer injection mold design, engineering, and building for our OEM customers. HENSEN offers the following injection molding services:

> Die Casting Tooling

> Precision Injection Mold Machining

> Plastic Injection Mold Manufacturing

> Plastic Injection Molding Part Service

> Plastics Insert molding

> Plastic Overmolding

> Silicone Rubber injection molding