Powerful manufacturers

Capable processing factories, reduced delivery time by 30%

We have various fully automatic and high-precision processing equipment such as precision lathes, 4-axis and 5-axis machining groups, and automatic CNC lathes. With high production efficiency and strong supply capacity, samples can be produced in 2 days and shipped as fast as 5 days, meeting the processing needs of different customers.

Strong team

Strong technical team, reducing costs and increasing efficiency for customers

The founder has been deeply involved in the industry for more than 10 years, with six skill research teams with over 6 years of industry experience. They are skilled in product structure and mold equipment, and can collaborate with customers to develop and design, helping them optimize their designs and improve the quality of spare parts.

Quality control

Strict quality control to ensure that products are qualified and leave the factory

It has a full set of testing equipment, such as contour measuring instrument, three-dimensional, anime, hardness tester, infrared automatic detector, roughness, etc. From material selection to delivery, each link is closely monitored, and each batch of products has undergone three precision tests to ensure that the products are qualified before delivery.

Guarantee services

to address customer concerns

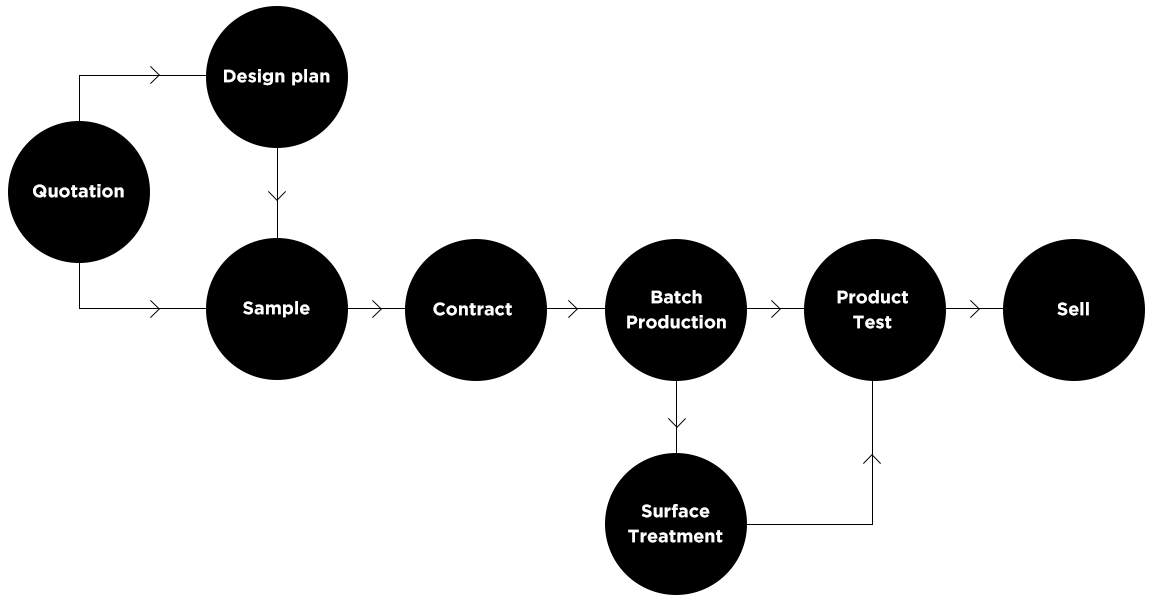

Pre sales: Provide engineer technical consulting services, collaborate with customers to develop and design, deeply optimize drawings, and provide sampling services;

After sales: Adhere to the principle of strict confidentiality for the customer's design proposal, and promise that the customer can provide rework and replacement services due to our own reasons.