Alloy steel contains trace amounts of one or more alloying elements (other than carbon), such as manganese, silicon, nickel, titanium, copper, chromium, and aluminum. Alloying provides it with unique qualities not present in standard carbon steel. Due to its low cost, wide availability, ease of processing, and superior mechanical rates, alloy steel is ideal for industrial applications. In general, alloy steels are more malleable to heat and mechanical treatment than carbon steels.

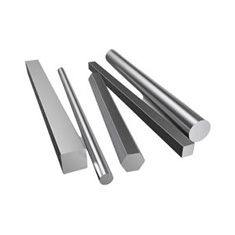

HENSEN offers a complete Alloy Steel CNC machining service and can produce custom Alloy Steel parts in various shapes and grades, including 4130, 4140, 4340, and more.